Figure 6.

Medbury, E. (2020) Fungi Solutions, Nicefilm Co. [Film Still] Mycelium composite block showing the root structure during cultivation with mycelium definition overlay.

Figure 7.

O’Donnel, E. Fungi Solutions Mycelium Materials, Wall Panel Installation, Product Display and Events Solutions, Eli May Photography, 2024.

LITERATURE REVIEW

Chapter 2 A Growing Biotechnology — Mycelium Materials in Review

Mycelium is the intricate network of root-like structures produced by fungi. The root mats of mycelium created by fungi as they grow are made of densely intermeshing fibers, that exhibit strong bonding properties that have in recent years been cultivated to create lightweight, durable, and insulating materials.

Mycelium-Based Materials represent a diverse and emerging category being explored in various industries, including construction, polystyrene alternatives, foams, and leathers. It is essential to recognize the range of applications, as well as the limitations and scope of testing these materials to achieve consistent results. Commonly, in both the literature and across these industries, mycelium-based materials are noted for the following properties:

Mycelium composites are low-cost to produce & made from agricultural waste feedstocks (Li et al., 2022).

Lightweight, airy structure created by the roots leads to production of durable materials when dried, with excellent compressive strength (Etinosa et al., 2024; Fairus et al., 2022; Ghazvinian et al., 2019; Haneef et al., 2017; Islam et al., 2018; Jones, Bhat, et al., 2018; Sun et al., 2022; Zhang et al., 2022).

Thermally and acoustically insulating due to the air pockets in mycelium formation (Fellah et al., 2024; Haneef et al., 2017; Zhang et al., 2022).

Fire retardant and self-extinguishing due to chitin present and char production (Gandia et al., 2021 & Yang, 2024).

Grown with low environmental impact, and low energy use (Wang et al., 2008) .

Carbon capturing and diverting organic waste resources from landfill decomposition releasing methane (Bhat et al., 2020; Gandia et al., 2021; Jones, Bhat, et al., 2018).

This study unfolds against the backdrop of a growing interest in understanding what can be grown, made, and replaced with fungal materials. To understand the complexities of the fungal materials technology, along with the potential applications for novel cultivation methods, it is crucial to examine the broader range of properties across the category of mycelium materials, followed by discussion of key papers and methods for cultivating mycelium for targeted applications. This is an in-depth review of the published materials characteristics of mycelium materials across construction, packaging, and textile applications to assess viability for novel material development in performance textile technology.

While the existing literature and academic exploration of Mycelium Materials technology and Biodesign in this area is an emerging field— with a range of recent literature published in the last 3 years in fungal materials discussed in this review, and it is an area worthy of further exploration in the context of safety and performance textiles.

-

One of the key performance properties of interest in relation to mycelium is the thermally protecting structure of the root network, that creates an airy bonded mesh that performs like a foam. This structure lends materials in this category to be useful for protective, lightweight, and insulating applications. The papers in this section explore mycelium composites for replacements for insulation in construction, interior surfaces, and wall panels.

The thermal properties of mycelium-based materials are attributed to the structure of the root mat of mycelium(Zhang et al., 2022), the presence of chitin, and the production of char, which provides self-extinguishing and protective properties(Chulikavit et al., 2023). The air pockets within the root structure provide a thermal protection layer, that protects from heat(Zhang et al., 2022). The structure of the roots, that contribute to the thermal insulation and the durability in forming a bonded material is shown in the figure below.

Char is an ash formed on the surface of a burned material, that reduces oxygen flow and limits combustion rates. Self-extinguishing materials (like wool, that is used as an accessible, natural fiber with fire protection properties) which do not continue burning once the heat source is removed. This combination of properties contributes to the overall function of a protective textile application such as fire blankets(Madrzykowski, 2017).

An overview of mycelium materials technology is explored in ‘Multi-scale analysis of the structure-mechanics relationship of mycelium-based bio-composites (Yang, 2024). This study reviewed the insulation properties of mycelium-based materials for construction applications and highlighted the need for continued development due to the current limitations in stiffness, flexibility, and durability of materials available. Yang utilized machine learning models to predict material performance under various conditions, presenting materials with enhanced compressive and tensile strengths.

A similar body of work, ‘Thermal insulation and energy performance’s assessment of a mycelium-based composite wall for sustainable buildings’ (Fellah et al. 2024) explored the thermal insulation properties of mycelium-based composite walls, finding superior insulation compared to conventional materials like concrete and gypsum.

In exploring the mycelium composites and the impact of species and substrate, ‘A study on the thermal performance of Pleurotus Ostreatus/Straw mycelium composites and its application in building envelopes’ (Jin et al. 2024), observed a wide range of thermal conductivity values, indicating excellent insulation properties.

In addition to thermally insulating qualities, discussions in ‘Novel strategies to grow natural fibers with improved thermal stability and fire resistance’ (Zhang, et al. 2021), and ‘Waste‐derived low‐cost mycelium composite construction materials with improved fire safety’ (Jones, et al. 2018) indicate that fire performance can be further enhanced in these materials by adjusting the cultivation conditions, species, cultivation feedstock, and surface treatment processes.

Key learning from the research into mycelium composites opens new avenues that could inform improvements to flexible fungal materials, such as cultivating leathers with high silicone content waste streams like ground glass for higher protection and higher weight applications, increasing the thermal performance of light weight leathers with aerated structures or improving the mechanical performance with composite layered materials.

-

The mechanical performance of MBLs is contributed by the formation of the aerial mycelium hide — the dense layer of surface mycelium that creates a dense mesh of roots. In the image below the bonding properties of the mycelium can be seen between the density of the the white areas of active aerial mycelium grown and the inner layers of the composite blocks that have less bonding through the roots.

Mechanical reviews of fungal materials include Mycelium Composites for Sustainable Development in Developing Countries: The Case for Africa (Akromah et al., 2024) reviewing the into the performance, structure and related mechanical properties of mycelium composites compared against High-Density Polyurethane (HDPU) and Polystyrene (XPS) yielded indications of similar thermal conductivity, and compressive strength, lower tensile strength – mycelium blocks do not resist torsion – such as twisting motions well and tend to break apart, but exhibit qualities that are protective, thermally insulating and biodegradable while HDPU and XPS are abundant pollutants and generators of microplastics.

In the exploration of the textile side of mycelium materials in ‘Flexible Fungal Materials: An Industrial Perspective’ by Kapoor et al. 2024 [10] discusses fungal mycelium offering a sustainable alternative to plastics, leather, and textiles due to its biodegradability and low energy requirements.

Diagrams to the right show the mechanical structure and cultivation processes used to grow, harvest and process mycelium into a flexible fungal material (FFM) with bonding, heat pressing and surface treatments. -

FFMs processed in this way – through crosslinking, heat pressing, bonding and surface treatments similarly to tanning Animal-Based Leathers to lend the hide good tensile strength and flexibility, with variations in properties based on the fungal species and substrates used. The paper Revolutionizing sustainable fashion: Jute-mycelium vegan leather reinforced with polyhydroxyalkanoate biopolymer crosslinking from novel bacteria by Akhter, et al. 2024, [2] demonstrated a tensile strength of 8.62 MPa and an elongation percentage of 8.34 for their composite MBL materials reinforced with jute and PHA (a bacteria derived bioplastic). The properties indicated in the literature situate the materials in line with performance standards for protective and structural textiles or offer avenues for improving compliance.

There is a broad range of findings in this material category depending on the cultivation conditions (species, substrate, inoculation method, growth conditions and surface treatments) of each study, but some larger themes of what applications suit the material properties, what are the limitations of their use, that inform the methodology of the material selection and testing discussed in Chapter 3.

Within the industry of mycelium materials, a limited number of commercially available culinary and medicinal species are typically used to make materials, these fungi have been at the center of the biomaterials innovations as mycology techniques formed in a do-it-yourself, home cultivator and open-source community, and these fungi are widely available. Many cultivation methods are distributed freely and there is an active network of cultivators growing and experimenting with mycelium. As the mycelium and growth conditions of these culinary and medicinal fungi are most accessible, many of the studies of fungal materials are conducted on similar species, with a few papers also exploring novel species for specific applications. As the range of species and substrates are common amongst many studies, performance results can be compared, while the research around novel species and strategies are able to provide insights into enhanced cultivation methods and tailored applications for the materials.

The most common materials listed a Ganoderma | Reshi species (for the dense mycelium growth habit), a Pleurotus | Oyster species (for the rapid growth habit and accessibility), or a small handful of commercially available fungi species. Common substrates are straw, grain and hardwoods. There are also novel native fungi species and local waste resources to be explored in future avenues of the project in more depth discussed in the future work sections.Mycelium has emerged as a compelling alternative to traditional and synthetic leather in the quest for sustainable and high-performance materials. Unlike animal-based leathers, mycelium offers rapid growth and a unique interwoven root structure that provides strong bonding capabilities. This combination of properties is not typically found in animal or plant-based leathers— which usually have a tradeoff of performance or ethics, making mycelium a promising regenerative material candidate for durability and strength applications.

Additionally, mycelium-based materials exhibit properties of partial wetting – a key factor in moisture management, compared to synthetic plastic-based leathers, which indicates suitability for enhancing comfort in worn applications. These properties position mycelium as a viable material for protective textiles, particularly in environments requiring thermal insulation and mechanical protection. The exploration of mycelium-based leathers (MBLs) could lead to key advancements in material technology, offering sustainable solutions with potential benefits for industries ranging from community emergency preparedness to firefighting turnout coats.

To explore the suitable combination of species, substrate, cultivation condition and processing techniques the material properties of the flexible fungal materials are discussed in this section, followed by a review of avenues for adapting the material properties to functional protective textiles.

Broadly, mycelium materials can be produced in a solid, block-like composite format, suitable for interiors and products, or as a flexible mat of the surface layer of roots (the aerial mycelium layer) which when harvested and treated, creates sheet-like flexible foams, leathers and papers. There are a variety of types of Flexible Fungal Materials (FFMs) in this category:Pure Mycelium Foams: Lightweight with high porosity, produced by species like Fusarium graminearum and Ganoderma carnosum, suitable for low-load shipping materials and lends towards acoustic and thermal applications.

Paper-like Materials: Made from fungal chitin, blended mushroom fruitbodies or pulps of mycelium and growth media. These materials resemble plant-derived cellulose style papers but exhibit improved moisture management, making them ideal for applications like watercolor paper, rather than print paper where a cotton rag style paper may usually be used for slow absorption of water improves the paper performance and prevents buckling.

Fungal Composites: Combine fungal mycelium with lignocellulosic materials like straw, or another embedded material for layered material benefits. Examples include embedding a backing material into the root mesh as it grows, rather than bonding with an adhesive. Living mycelium exhibits excellent fusing potential for joining materials without glue, hardware or mechanical finishing.

-

Future work in this direction would support the development of novel cultivation methods, avenues for enhanced feedstock and species selection targeted to fire- resistance enhancing waste feedstocks and new technical applications for fungal materials. The project activities towards a more advanced understanding of these materials are impactful because of the layered benefits of waste resources captured, regenerative manufacturing of improved materials for further review and industry development.

Following on from the exploration of thermal insulation properties more broadly into the relationship with fire safety and protective performance, (Yang, 2024) indicated that mycelium-based composites exhibit good thermal stability, with decomposition temperatures above 250°C. The materials produced stable char consisting primarily of amorphous carbon that started to form at 500°C, with a drop in mass of 25% at higher temperatures. This situates raw mycelium composites in a similar performance range to wool, (Decomposition Temperature 218 - 390°C, Mass Loss 51%) which also has self-extinguishing properties and is used along with aramids (heat resistant, synthetic fibers) for fire blankets.

Mycelium composites have also been investigated (Jones et al. 2018) in ‘Waste-derived low-cost mycelium composite construction materials with improved fire safety’ as an alternative to traditional construction materials in terms of fire safety performance. This study aimed to evaluate the thermal degradation characteristics and fire reaction properties of mycelium composites using different substrates. Jones found that substrates with a higher silica content improved the char production and fire performance of the mycelium.

Glass fines and rice hulls were identified as two low-cost and abundant waste streams with high silica content. Additional sources of high silica, and other char producing waste streams are discussed in future work.

One constraint of the commercially available MBL materials is the bonded backing included to increase the tensile strength of the aerial mycelium mat in line with leather durability. In burn testing the backing and adhesive contributed to bucking of the material when exposed to flame. The backing is bonded with an EVA glue adhesive which does not align with the requirements of structural turnout applications, but the material may be adjusted in the cultivation process to improve durability with embedded fibers.

Optimizing composite processing methods could enhance performance and expand applicability (Zhang et al. 2021) found that incorporating fire retardant additives significantly improved the fire resistance of natural fibers while a series of studies by Jones from 2017-2020 demonstrated that mycelium materials can be adapted by increasing the silica content of waste substrates to enhance the fire performance of mycelium composites, and species selection for performance properties(Jones et al., 2020; Jones, Huynh, et al., 2017, 2018) . This expands applications for mycelium into industries with stringent fire codes, such as interiors and performance textiles.

The findings from the thermal insulation literature references on mycelium materials define the scope of this study in technical textiles. Their excellent thermal insulation and heat resistance make them suitable for applications related to comfort, safety, and protection. The next section will analyze the fire reaction properties of mycelium composites and the mechanical properties of flexible fungal materials like leathers, foams, and mats. This analysis will inform the research proposal in the following chapter.

Fire Performance Analysis

The exploration of non-combustible natural materials presents a significant opportunity to enhance safety and sustainability across various industrial and social applications. Non-combustible materials are designed to withstand extreme temperatures and resist ignition, and smother oxygen to starve flames of combustion. As such, non-combustible materials play a vital role in safeguarding structures, equipment, and environments from the devastating effects of fires.

This following Methodology Chapter examines the benchmarking requirements for non-combustible materials, focusing on their unique properties and practical applications. To assess the viability of novel flexible fungal materials, the materials have been tested against NFPA 1971: The Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting as well as key Industrial Standards — ISO 13937: Textiles - Tear properties of fabrics, ASTM D4966-22: Abrasion Martindale, ISO 9237: Textiles - Determination of the permeability of fabrics to air, ISO 11092: 2014 Textiles - Physiological effects - Measurement of thermal and water-vapor resistance under steady-state conditions (sweating guarded-hotplate test) wet & dry method.

Exploration of the mechanical and thermal performance of the Enhanced Mycelium-Based Leather materials cultivated for this research project indicates properties in line with the performance requirements, suggesting applications in fire-resistant and non-combustible materials outlined in the following chapter.

Jones’s studies into mycelium in architectural applications found that mycelium composites exhibited lower HRR (Heat Release Rate) values compared to traditional construction materials (MDF and plywood) suggesting that mycelium composites would provide a safer construction material in the event of a fire (Jones, Bhat, et al., 2017; Jones, Huynh, et al., 2017). The average HRR of rice hull-based mycelium composite was 85 kW/m², which is significantly less than that of Extruded Polystyrene (XPS is a high-performing, rigid foam insulation board with a HRR of 114 kW/m²) and particleboard (MDF a synthetic bonded woodchip material with a HRR of 134 kW/m²).

The requirement for non-combustibility becomes a HRR of 106 kW/m2 or less when irradiated at a thermal flux of 50 kW/m2 in an atmosphere containing 40 % oxygen. This situates mycelium composites within protective HRR ranges for non-combustibility.

In Strategies for growing large-scale mycelium structures (Dessi-Olive , 2022), noted that mycelium materials had a ‘flame spread resistance comparable to gypsum’ which is rated as a Class Afire rated material with a score of 15. Class A fire ratings indicate a flame spread rating somewhere between zero and 25. Materials that fall into Class A or Class 1 include things like brick, gypsum wallboard, and fiber cement exterior materials. These materials do not burn well and are very unlikely to contribute fuel to a fire.

The findings of 'Waste-derived low-cost mycelium composite construction materials with improved fire safety’(Jones, Bhat, et al., 2018) indicated that the reduced heat release rates of mycelium composites resulted in longer estimated times to flashover compared to traditional construction materials. The samples were cultivated on Trametes Versicolor (Turkey Tail Species similar to Reshi in growth habit and mycelium formation) on a substrate with 25 and 75% rice hulls or 50% glass fines to compared against XPS and MDF.

The estimated time to flash-over shown by the glass fines sample was calculated based on the material density of 450 kg/m3, heat release rate of 85 kW/m².

Mycelium composites exhibited longer times to flashover compared to traditional construction materials, with rice hull-based mycelium composite containing glass fines having the longest time (311 seconds) Jones writes that ‘the addition of glass waste significantly increased the silica content of the composite materials which is known to reduce flammability and smoke yield through fuel dilution and heat sink mechanisms.

Additionally the silica inclusions reduced the concentration of flammable organics (e.g. cellulose) which are known to fuel combustion’. This study demonstrates the potential of mycelium composites as a fire-safe building material, with rice hull-based and wheat grain-based compositions incorporating glass fines exhibiting superior performance characteristics. This indicates that it is possible to improve the performance of flexible mycelium materials and create opportunities to study them for protective textile applications with opportunities to explore other high silica waste streams like rice, straw and sugarcane.

Key Findings of ‘Novel Strategies to Grow Natural Fibers with Improved Thermal Stability and Fire Resistance’ (Zhang et al., 2021) found that the addition of silica (SI) improved the thermal stability and fire resistance of fungi composites. A low concentration of Si accelerated the growth of the mycelium composites while high concentrations inhibited growth, suggesting an upper limit for thermal improvement by this method due to the impact on the fungal metabolism.

The materials were assessed by Thermogravimetric Analysis (TGA and showed improved residual weight with the inclusion of SI in Pleurotus ostreatus and Fusarium oxysporum species composites, which retained more weight compared to synthetic fibers. Adding 3% Si to Fusarium oxysporum in cultivation increased residual weight by 93.81% and reduced the peak heat release rate and total heat of combustion by 50% and 35.09%, respectively.

Fourier Transform Infrared (FTIR) spectra confirmed the interaction between Si and fungal fibers, showing Si incorporation into the fibers. Scanning Electron Microscopy (SEM) revealed changes in fiber surface structure with Si enrichment, including shrinkage and structural flexibility due to Si-induced enzyme activity. The Si source acted as a crosslinker, promoting the formation of protective char during combustion, enhancing fire resistance.

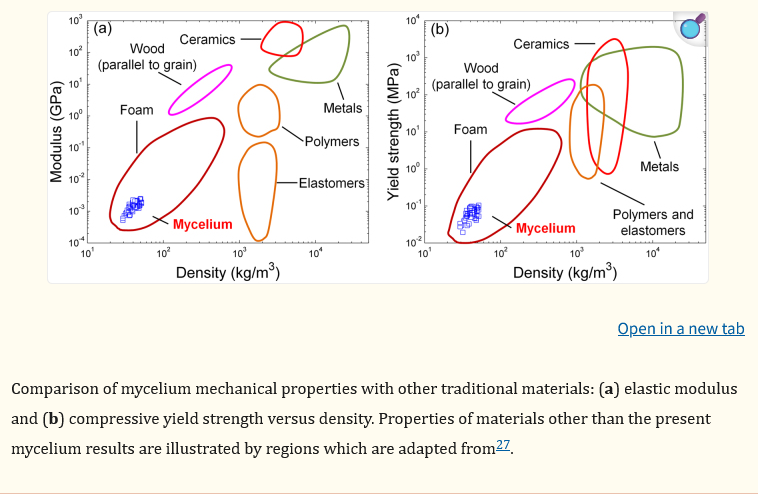

Figure 8.

Islam et al. (2013) Morphology mechanics of fungal mycelium. Sci Rep. 2017 Oct 12 showing the elastic modulus and compressive strength of a group of mycelium composites in relation to other material groups such as foam, wood, ceramics, metals, polymers and elastomers.

Figure 9.

Medbury, E. (2021). Fungi Solutions, REIMAGINE WASTE Stream Visual Assets Mycelium. Mycelium composites show excellent bonding, fusing, and insulation properties. The white sections of actively growing mycelium show the most strongly bonded areas.

Photography credit name

Make up credit name

Publication credit name

Figure 6.

Medbury, E. (2020) Fungi Solutions, Nicefilm Co. [Film Still] Mycelium composite block showing the root structure during cultivation with mycelium definition overlay.

Figure 7.

O’Donnel, E. Fungi Solutions Mycelium Materials, Wall Panel Installation, Product Display and Events Solutions, Eli May Photography, 2024.

LITERATURE REVIEW

Chapter 2 A Growing Biotechnology — Mycelium Materials in Review

Mycelium is the intricate network of root-like structures produced by fungi. The root mats of mycelium created by fungi as they grow are made of densely intermeshing fibers, that exhibit strong bonding properties that have in recent years been cultivated to create lightweight, durable, and insulating materials.

Mycelium-Based Materials represent a diverse and emerging category being explored in various industries, including construction, polystyrene alternatives, foams, and leathers. It is essential to recognize the range of applications, as well as the limitations and scope of testing these materials to achieve consistent results. Commonly, in both the literature and across these industries, mycelium-based materials are noted for the following properties:

Mycelium composites are low-cost to produce & made from agricultural waste feedstocks (Li et al., 2022).

Lightweight, airy structure created by the roots leads to production of durable materials when dried, with excellent compressive strength (Etinosa et al., 2024; Fairus et al., 2022; Ghazvinian et al., 2019; Haneef et al., 2017; Islam et al., 2018; Jones, Bhat, et al., 2018; Sun et al., 2022; Zhang et al., 2022).

Thermally and acoustically insulating due to the air pockets in mycelium formation (Fellah et al., 2024; Haneef et al., 2017; Zhang et al., 2022).

Fire retardant and self-extinguishing due to chitin present and char production (Gandia et al., 2021 & Yang, 2024).

Grown with low environmental impact, and low energy use (Wang et al., 2008) .

Carbon capturing and diverting organic waste resources from landfill decomposition releasing methane (Bhat et al., 2020; Gandia et al., 2021; Jones, Bhat, et al., 2018).

This study unfolds against the backdrop of a growing interest in understanding what can be grown, made, and replaced with fungal materials. To understand the complexities of the fungal materials technology, along with the potential applications for novel cultivation methods, it is crucial to examine the broader range of properties across the category of mycelium materials, followed by discussion of key papers and methods for cultivating mycelium for targeted applications. This is an in-depth review of the published materials characteristics of mycelium materials across construction, packaging, and textile applications to assess viability for novel material development in performance textile technology.

While the existing literature and academic exploration of Mycelium Materials technology and Biodesign in this area is an emerging field— with a range of recent literature published in the last 3 years in fungal materials discussed in this review, and it is an area worthy of further exploration in the context of safety and performance textiles.

-

One of the key performance properties of interest in relation to mycelium is the thermally protecting structure of the root network, that creates an airy bonded mesh that performs like a foam. This structure lends materials in this category to be useful for protective, lightweight, and insulating applications. The papers in this section explore mycelium composites for replacements for insulation in construction, interior surfaces, and wall panels.

The thermal properties of mycelium-based materials are attributed to the structure of the root mat of mycelium(Zhang et al., 2022), the presence of chitin, and the production of char, which provides self-extinguishing and protective properties(Chulikavit et al., 2023). The air pockets within the root structure provide a thermal protection layer, that protects from heat(Zhang et al., 2022). The structure of the roots, that contribute to the thermal insulation and the durability in forming a bonded material is shown in the figure below.

Char is an ash formed on the surface of a burned material, that reduces oxygen flow and limits combustion rates. Self-extinguishing materials (like wool, that is used as an accessible, natural fiber with fire protection properties) which do not continue burning once the heat source is removed. This combination of properties contributes to the overall function of a protective textile application such as fire blankets(Madrzykowski, 2017).

An overview of mycelium materials technology is explored in ‘Multi-scale analysis of the structure-mechanics relationship of mycelium-based bio-composites (Yang, 2024). This study reviewed the insulation properties of mycelium-based materials for construction applications and highlighted the need for continued development due to the current limitations in stiffness, flexibility, and durability of materials available. Yang utilized machine learning models to predict material performance under various conditions, presenting materials with enhanced compressive and tensile strengths.

A similar body of work, ‘Thermal insulation and energy performance’s assessment of a mycelium-based composite wall for sustainable buildings’ (Fellah et al. 2024) explored the thermal insulation properties of mycelium-based composite walls, finding superior insulation compared to conventional materials like concrete and gypsum.

In exploring the mycelium composites and the impact of species and substrate, ‘A study on the thermal performance of Pleurotus Ostreatus/Straw mycelium composites and its application in building envelopes’ (Jin et al. 2024), observed a wide range of thermal conductivity values, indicating excellent insulation properties.

In addition to thermally insulating qualities, discussions in ‘Novel strategies to grow natural fibers with improved thermal stability and fire resistance’ (Zhang, et al. 2021), and ‘Waste‐derived low‐cost mycelium composite construction materials with improved fire safety’ (Jones, et al. 2018) indicate that fire performance can be further enhanced in these materials by adjusting the cultivation conditions, species, cultivation feedstock, and surface treatment processes.

Key learning from the research into mycelium composites opens new avenues that could inform improvements to flexible fungal materials, such as cultivating leathers with high silicone content waste streams like ground glass for higher protection and higher weight applications, increasing the thermal performance of light weight leathers with aerated structures or improving the mechanical performance with composite layered materials.

-

The mechanical performance of MBLs is contributed by the formation of the aerial mycelium hide — the dense layer of surface mycelium that creates a dense mesh of roots. In the image below the bonding properties of the mycelium can be seen between the density of the the white areas of active aerial mycelium grown and the inner layers of the composite blocks that have less bonding through the roots.

Mechanical reviews of fungal materials include Mycelium Composites for Sustainable Development in Developing Countries: The Case for Africa (Akromah et al., 2024) reviewing the into the performance, structure and related mechanical properties of mycelium composites compared against High-Density Polyurethane (HDPU) and Polystyrene (XPS) yielded indications of similar thermal conductivity, and compressive strength, lower tensile strength – mycelium blocks do not resist torsion – such as twisting motions well and tend to break apart, but exhibit qualities that are protective, thermally insulating and biodegradable while HDPU and XPS are abundant pollutants and generators of microplastics.

In the exploration of the textile side of mycelium materials in ‘Flexible Fungal Materials: An Industrial Perspective’ by Kapoor et al. 2024 [10] discusses fungal mycelium offering a sustainable alternative to plastics, leather, and textiles due to its biodegradability and low energy requirements.

Diagrams to the right show the mechanical structure and cultivation processes used to grow, harvest and process mycelium into a flexible fungal material (FFM) with bonding, heat pressing and surface treatments. -

FFMs processed in this way – through crosslinking, heat pressing, bonding and surface treatments similarly to tanning Animal-Based Leathers to lend the hide good tensile strength and flexibility, with variations in properties based on the fungal species and substrates used. The paper Revolutionizing sustainable fashion: Jute-mycelium vegan leather reinforced with polyhydroxyalkanoate biopolymer crosslinking from novel bacteria by Akhter, et al. 2024, [2] demonstrated a tensile strength of 8.62 MPa and an elongation percentage of 8.34 for their composite MBL materials reinforced with jute and PHA (a bacteria derived bioplastic). The properties indicated in the literature situate the materials in line with performance standards for protective and structural textiles or offer avenues for improving compliance.

There is a broad range of findings in this material category depending on the cultivation conditions (species, substrate, inoculation method, growth conditions and surface treatments) of each study, but some larger themes of what applications suit the material properties, what are the limitations of their use, that inform the methodology of the material selection and testing discussed in Chapter 3.

Within the industry of mycelium materials, a limited number of commercially available culinary and medicinal species are typically used to make materials, these fungi have been at the center of the biomaterials innovations as mycology techniques formed in a do-it-yourself, home cultivator and open-source community, and these fungi are widely available. Many cultivation methods are distributed freely and there is an active network of cultivators growing and experimenting with mycelium. As the mycelium and growth conditions of these culinary and medicinal fungi are most accessible, many of the studies of fungal materials are conducted on similar species, with a few papers also exploring novel species for specific applications. As the range of species and substrates are common amongst many studies, performance results can be compared, while the research around novel species and strategies are able to provide insights into enhanced cultivation methods and tailored applications for the materials.

The most common materials listed a Ganoderma | Reshi species (for the dense mycelium growth habit), a Pleurotus | Oyster species (for the rapid growth habit and accessibility), or a small handful of commercially available fungi species. Common substrates are straw, grain and hardwoods. There are also novel native fungi species and local waste resources to be explored in future avenues of the project in more depth discussed in the future work sections.Mycelium has emerged as a compelling alternative to traditional and synthetic leather in the quest for sustainable and high-performance materials. Unlike animal-based leathers, mycelium offers rapid growth and a unique interwoven root structure that provides strong bonding capabilities. This combination of properties is not typically found in animal or plant-based leathers— which usually have a tradeoff of performance or ethics, making mycelium a promising regenerative material candidate for durability and strength applications.

Additionally, mycelium-based materials exhibit properties of partial wetting – a key factor in moisture management, compared to synthetic plastic-based leathers, which indicates suitability for enhancing comfort in worn applications. These properties position mycelium as a viable material for protective textiles, particularly in environments requiring thermal insulation and mechanical protection. The exploration of mycelium-based leathers (MBLs) could lead to key advancements in material technology, offering sustainable solutions with potential benefits for industries ranging from community emergency preparedness to firefighting turnout coats.

To explore the suitable combination of species, substrate, cultivation condition and processing techniques the material properties of the flexible fungal materials are discussed in this section, followed by a review of avenues for adapting the material properties to functional protective textiles.

Broadly, mycelium materials can be produced in a solid, block-like composite format, suitable for interiors and products, or as a flexible mat of the surface layer of roots (the aerial mycelium layer) which when harvested and treated, creates sheet-like flexible foams, leathers and papers. There are a variety of types of Flexible Fungal Materials (FFMs) in this category:Pure Mycelium Foams: Lightweight with high porosity, produced by species like Fusarium graminearum and Ganoderma carnosum, suitable for low-load shipping materials and lends towards acoustic and thermal applications.

Paper-like Materials: Made from fungal chitin, blended mushroom fruitbodies or pulps of mycelium and growth media. These materials resemble plant-derived cellulose style papers but exhibit improved moisture management, making them ideal for applications like watercolor paper, rather than print paper where a cotton rag style paper may usually be used for slow absorption of water improves the paper performance and prevents buckling.

Fungal Composites: Combine fungal mycelium with lignocellulosic materials like straw, or another embedded material for layered material benefits. Examples include embedding a backing material into the root mesh as it grows, rather than bonding with an adhesive. Living mycelium exhibits excellent fusing potential for joining materials without glue, hardware or mechanical finishing.

Figure 8.

Islam et al. (2013) Morphology mechanics of fungal mycelium. Sci Rep. 2017 Oct 12 showing the elastic modulus and compressive strength of a group of mycelium composites in relation to other material groups such as foam, wood, ceramics, metals, polymers and elastomers.

Figure 9.

Medbury, E. (2021). Fungi Solutions, REIMAGINE WASTE Stream Visual Assets Mycelium. Mycelium composites show excellent bonding, fusing, and insulation properties. The white sections of actively growing mycelium show the most strongly bonded areas.

Photography credit name

Make up credit name

Publication credit name